The building sector is affected by a wide variety of problems. One of the most important issues concerning this industry is workplace safety. In the U.S., construction represented one of the most dangerous areas to work in as it held the first place for workplace fatalities in 2015 (most recent data available) with 937 casualties, a sad 4 percent increase from the previous year. Additionally, the industry is also afflicted by a severe skilled-labor shortage, causing over 60% of contractors to struggle to find suitable staff for their sites.

Nevertheless, demand for workers has not slowed down. On the contrary, recent natural disasters such as hurricane Irma and Harvey have spiked the demand for construction workers in an effort to rebuild the facilities and infrastructures destroyed by these hurricanes.

Fortunately, economic conditions and new technological advances have allowed the industry to take a proactive approach towards problem-solving and growth. Below, we will present to you two state-of-the-art solutions from different companies tackling these problems in the area of bridge construction.

- Tybot

- MX3D Bridge

Tying rebar is one of the most critical processes in the construction of a bridge. This tedious task can cause health issues such as back problems. Moreover, slips and falls represent the number one reason for accidents in the sector, putting workers from these types of projects at a higher risk of more serious injuries.

Steve Muck, CEO, and Chairman of Brayman Construction Corp., along with Jeremy Searock, former Technical Program Manager at the National Robotics Engineering Center at Carnegie Mellon University, decided to tackle this problem with a very innovative solution.

They decided to build a robot capable of tying rebar which they called “Tybot.” This ingenious solution tremendously enhances this process as the robot only requires one supervisor to operate the machine. “Tybot” is able to expand as much as 140 feet across the width of a bridge and its robotic arm can automatically detect intersections to tie rebar, potentially saving hundreds of dollars in labor cost but also considerably decreasing injuries and liabilities in the area of bridge construction.

In addition to its numerous benefits, this solution is not far away from the future as the CEO expressed the robot is almost ready for entering the market with a cost that would improve the profitability of sites.

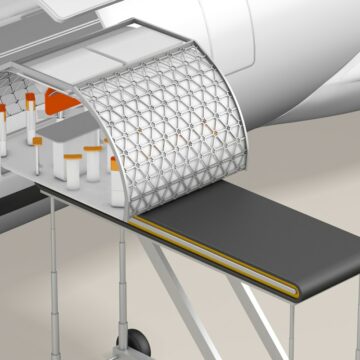

The Dutch company MX3D aims to revolutionize the large-scale 3D printing industry. To accomplish this task, they are working on a very cutting-edge project: the first 3D printed steel bridge. The company has developed a new 3D printer design by attaching a 6-axis industrial robotic arm to the printer to allow for more flexibility in the process.

The bridge was designed by Joris Laarman, a renowned Dutch designer, famous for working with pioneering technology. Initially, the bridge was conceived to be located at the center of Amsterdam. However, difficulties arose, and the project is now in progress at MX3D headquarters, expecting to be finalized for early 2018.

Although this project is not solving an essential need as the city of canals already possesses an exhaustive network of bridges, and 3D printing remains cost-prohibitive. The project hopes to showcase all the potential applications of this new technology such as more sustainable constructions due to less waste from additive manufacturing, less human errors and flexible schedules as the machines can operate continuously without any time wasted or fatigue, among many others benefits.

However, as expressed by the designer, the 3D printing industry has impacted more than labor and sustainability. It has disrupted a wide range of constructions processes. Such is the case for design, now architects and designers need to work with engineers and other construction professionals simultaneously whereas previously, this consisted of a step-by-step process. Another great benefit of using robots and 3D printing for construction is machine learning, potentially improving productivity on a construction site through the use of AI.

In conclusion, these projects allow us to get a sneak peak of what the future of bridge construction will look like as well as pushing other businesses towards modernization. Hopefully, we will soon be looking at greener and safer infrastructures for everyone.