In September 2013, Tokyo was announced as the host city for the 2020 Summer Olympics. Since this announcement, Japan started to build thousands of new construction projects including stadiums and hotels among many others urban improvements. However, due to the shortage of construction workers available, many of these constructions were facing obstacles.

Japan’s labor shortage is becoming more and more problematic as its aging population has left few young people available to operate heavy construction machinery. According to Japan’s ministry of Land, Infrastructure, Transport and Tourism, people under 29 years only account for 10% of the construction workforce. This situation has left the government and the construction industry worried about the future.

Fortunately, Komatsu, seller of bulldozers, forklifts and the second largest construction company in the world, has stepped up and offered a new solution to the workforce shortage crisis in Japan. Their solution: self-driving construction vehicles. This new technology hopes to help businesses fight the decrease of availability of construction workers by offering semi-autonomous vehicles. The technology is called Intelligent Machine Control and it allows the possibility of reducing the number of workers per sites.

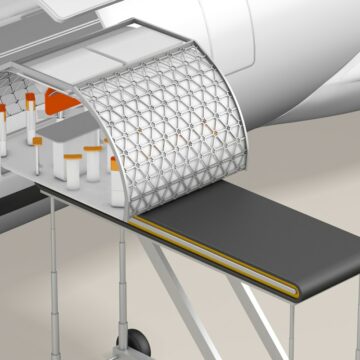

Initially, Komatsu faced difficulties with their technology as the vehicles could not be as precise as traditional construction workers, however, after teaming up with the American dronemaker Skycatch, this problem was resolved. Thanks to Skycatch, now these semi-autonomous vehicles are incredible accurate and much faster at mapping sites than humans.

In order to fully prepare a site with this technology, first drones need to fly over the location and take pictures of the ground. After this first step is finished, specialized software, using the data from the drones and 3D laser scanners, will create a three-dimensional map of the site and allocate the tasks for the vehicles. Then, the vehicles will start preparing the terrain by pushing dirt and rocks under the eye of a remote employee who supervises and tracks the activity of these machines. This innovative technology does not only decrease the number of workers in the field, but also lowers the skill level required for this type of job as the vehicles are equipped with highly effective sensors and software which makes the preparation of the terrain extremely straightforward as well as fast, reducing up to 60 percent of the time spent on preparing a site’s foundation. Although, one or two supervisors are still required in the field for safety reasons, this technology is bringing us closer to fully automated sites.

Komatsu is not currently selling these vehicles however, it is offering this technology as a service called SmartConstruction, allowing businesses who are struggling to find workforce to continue their activities smoothly. While this technology is only available in Japan for now, we can be hopeful for its success and expect it to be available in other countries in the future.